Citric Acid Passivation

Most of our customers require parts to be passivated prior to us applying dry film lubricant, however most do not perform this service themselves, so they must send parts to a passivation company before sending them to us. In some instances, the parts are sent back to the machine shop for inspection and then sent to us; this adds time to the procurement process and extra costs for shipping in the supply chain, which we aim to reduce with the implementation of our passivation process.

Key Benefits of Citric Acid Passivation

Environmentally safe chemistry – easy to use and dispose

Low workplace hazard chemistry – no toxic or corrosive fumes

Meets all current industry standards

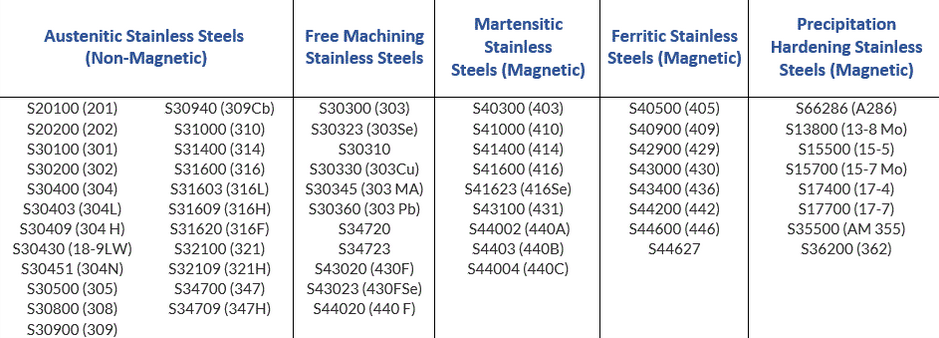

Excellent results with all grades of stainless steel

Improved, faster removal of free iron from the surface

Removes only iron, preserving other metals in alloy

Industry Standards for Citric Acid Passivation

Most acceptance criteria falls under one of two industry standards for citric acid passivation: ASTM A967 and AMS 2700.

ASTM A967 pertains to chemical treatments for passivation of stainless steel parts. The citric acid process is subdivided into 5 categories. Citric 1-3 specify solution strengths of 4-10% citric acid (by weight of composition), with shorter treatment times at higher temperatures. Citric 4 and 5 allow for other parameters, including the use of additives.

AMS 2700 pertains to the passivation of corrosion-resistant steels. This standard is used in the aerospace industry. As with ASTM A967, it set standards for citric acid (Method 2) immersion treatments. The Method 2 citric acid passivation standard specifies solution strengths of 4-10% citric acid (by weight of composition), with shorter treatment times at higher temperatures.

We also perform citric acid cleaning & passivation per ASTM A380 Code N.

NOTE: At this time, we are only accepting orders for ASTM A380 code N due to high volumes. For quotes of other specifications, please contact us.