Optimal Surface Finish for Tungsten Disulfide and Molybdenum Disulfide

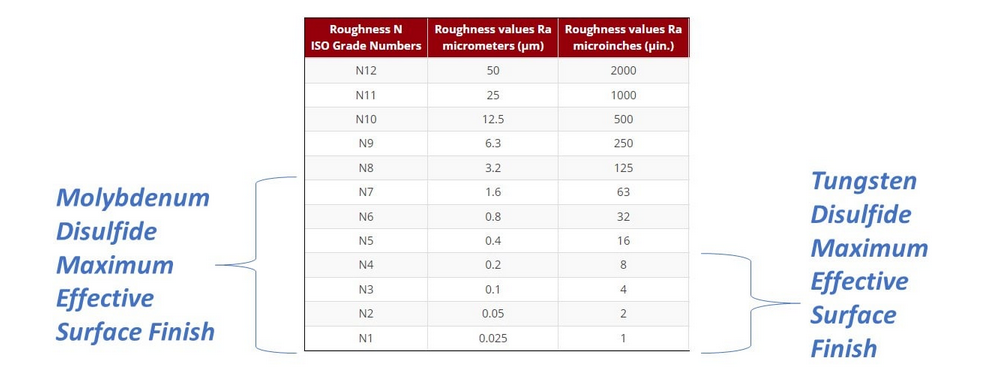

Having a surface with an exceedingly low coefficient of friction is a key benefit of WS2 and MoS2 coatings, however wear is another important aspect of a dry film coating which should be considered for any application, as coating wear properties are directly correlated to the surface finish of the substrate. There is no minimum surface finish WS2 and MoS2 can be applied to, however there is an effective maximum surface finish; if the surface finish (RA) is greater than the particle size of the coating material, the particles will sit, partially or in total, below the mating surface of the part. This leads to force concentrating onto the coating at the peaks of the surface finish, which in turn increases both the rate of wear of the coating as well as the friction. A general rule of thumb is that any surface finish of RA <=19 will work with both WS2 and MOS2, however surfaces with an RA >19 will perform better using MoS2.

In this diagram, the blue dots represent .5μm tungsten disulfide particles applied onto two surfaces of varying roughness. In the first image, the surface roughness is smaller than the particle size of the WS2 coating (.5μm = 19.7 microinches), allowing the mating surface to maximize contact with the lubricant coating. Any surface finish higher than 19.7 microinches will cause the WS2 particles to partially sit in the valleys of substrate, as shown in the lower figure. This reduces the area of contact the mating surface has with the coated substrate, subsequently reducing the effectiveness of the coating and increasing the rate of wear.

As the particles on the peaks of the surface shear apart during wear they will fill in the valleys of the surface, however as the surface wears further it will entirely wear the WS2 off of the peaks and erode the substrate surface before the WS2 in the valleys is exposed. Molybdenum disulfide also exhibits this behavior because of its similar structure; however, its larger particle size allows it to work more effectively on surfaces with much rougher surface finishes of up to RA 197.