Friction and Wear Testing of Tungsten Disulfide & Molybdenum Disulfide

Tungsten disulfide and molybdenum disulfide are both members of the "transition metal dichalcogenide" family of compounds with a similar lamellar crystalline structure which lends them their signature lubricity. However, not all coatings of either type are the same; the film thickness and coefficient of friction can vary depending on application method, humidity, surface finish, contamination, oxidation, and material purity.

Molybdenum disulfide was being used almost two decades before WS2 was discovered. WS2 is believed to have the lowest coefficient of friction. It it possible under certain applications but, for decades after the discovery of WS2 it was still being reported in NASA public reports that tungsten disulfide has a higher coefficient of friction that molybdenum disulfide [iii] which coincides with our friction testing results.

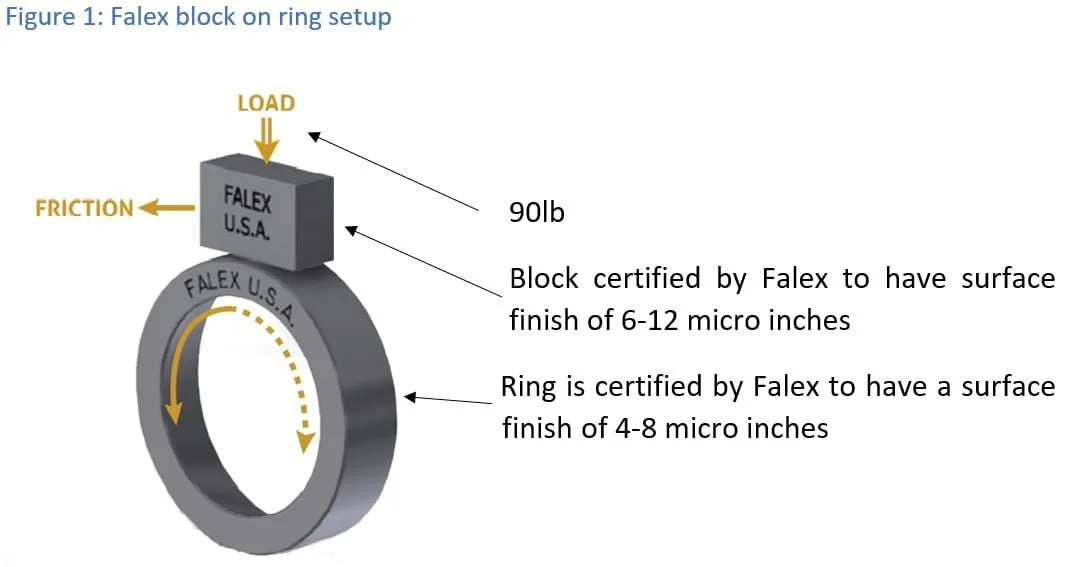

We measure the coefficients of friction of our coatings in accordance with the ASTM D2714 specification, as it is required for two different SAE impingement lubrication standards including AMS 2526 (MoS2) and AMS 2525 (graphite); AMS 2530 (WS2) does not require this test.

ASTM D2714 tests dynamically measure the coefficient of friction and sliding wear over time. The test machine is operated using a steel test block that is held stationary and a vertical force is applied to the block while a steel ring is rotated at a set speed. Per the AMS 2526 specification the test is ran with a ring speed of 72rpm with 90lb load, and to pass the time to failure of the coating shall not be less than 15 minutes. There is no specific quantitative value for what constitutes a failure so, we are using a coefficient value of .5 for the molybdenum disulfide failure point. For comparison, we also evaluated tungsten disulfide to see if it could pass the 15-minute test period to these same parameters.

Friction and Wear of Tungsten Disulfide

Our coefficient of friction begins .09 and begins to rise steadily at 4 minutes until 12 minutes. In the next 3 minutes the coefficient of friction doubled indicating the coating was about worn off. At the finish of the test the coefficient of friction was near the kinetic coefficient of friction for steel on steel.

Friction and Wear of Molybdenum Disulfide

Molybdenum Disulfide is much more commonly used than Tungsten Disulfide due to its lower cost and larger size, which makes it better for use in bake-on coatings or as a co-lubricant in greases. These two methods both have their downsides however; bake-on coatings require an organic binder, are 8-13um thick, and often have an uneven thickness, particularly on threads; and greases cannot be used in every application for a variety of reasons.

F.A.S.T. has combined the best of both worlds between impinged WS2 coatings and baked-on MoS2 coatings: impinged MoS2 coatings per AMS 2526. Our impinged MoS2 coatings provide the even finish of WS2 coatings, are less than 5um thick, and do not use an organic binder to adhere to a substrate.

We tested our impinged MoS2 coatings using the same method and parameters as for WS2 above, and the resulting graph is below.

After the run-in period of 10 minutes, the coefficient of friction was as low as .06. After the 15 minutes required for acceptance, the coefficient of friction was just .08; this is approximately 82% lower than tungsten disulfide at the same time interval.

There was a rise in the coefficient of friction from 190 to 309 minutes, when the test was stopped due to reaching the approximate metal-on-metal kinetic coefficient of .5.

Compared to the WS2 coating applied to the AMS 2530 specification, the MoS2 coating applied to the AMS 2526 specification yielded a significantly longer wear life and lower coefficient of friction average during the 15-minute testing interval. In order to ensure the validity of our testing, we repeated our testing a second time and found similar results. These results seem to contradict most of the readily available information about MoS2 and WS2 coatings from both our competitors and WS2 suppliers, who claim that WS2 should have a noticeably lower coefficient of friction than MoS2 – why? While we cannot say where this idea came from, we can show that other researchers have also found that MoS2 coatings have lower coefficients of friction than WS2[i] and can potentially reach below WS2’s theoretical minimum coefficient of .03[ii].

[i] K.C. Wong; X. Lu; J. Cotter; D.T. Eadie; P.C. Wong; K.A.R. Mitchell (2008). Surface and friction characterization of MoS2 and WS2 third body thin films under simulated wheel/rail rolling–sliding contact., 264(7-8), 526–534. doi:10.1016/j.wear.2007.04.004

[ii] Khare, H. S. (2014). The Coupled Effects Of Environmental Composition, Temperature And Contact Size-Scale On The Tribology Of Molybdenum Disulfide (dissertation). ProQuest LLC, Ann Arbor, MI.

[iii] Kannel, J. W. (November 22nd, 1991). Lubricant Selection Manual, Phase 3. Battelle Columbus Labs