Out-gassing of Tungsten Disulfide and Molybdenum Disulfide

Out-gassing is a property of a material that expresses its weight loss and tendency to condense onto a colder surface when tested at an elevated temperature [i]. The test required for out-gassing for tungsten disulfide listed in the AMS 2530 specification is ASTM E595. There is not an out-gassing test required for molybdenum disulfide under AMS 2526 but, we tested it for comparison to tungsten disulfide.

From the ASTM E595 specification paragraph 1.5 – The criteria used for the acceptance and rejection of materials shall be determined by the user and based upon specific component and system requirements. Historically, a total mass loss (TML) of 1.00% and collected volatile condensable material (CVCM) of .10% have been used as screening levels for rejection of spacecraft materials.

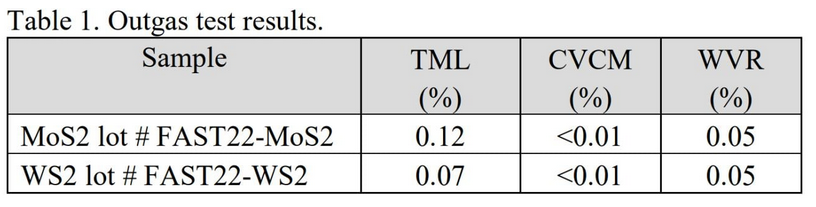

For this test we send out a 2-gram sample of material to an ISO/IEC 17025:2017 accredited lab. The test is performed in a vacuum environment of less than 5 x 10-5 Torr for a duration of 25hrs at 125 degrees C. Here is an example of our previous WS2 & MoS2 out-gassing test results:

Our total mass loss changes slightly from lot to lot but, never exceeds the 1.00% limit. This test is not viewed as a requirement by most of our competitors for the AMS 2530 specification so, they do not test for it. We perform this test on every lot number to ensure a quality product to our customers.

Here is some out-gassing test results from NASA. The testing was from 1969, around the time tungsten disulfide was starting its use as a space lubricant. This testing was prior to NASA standardizing on out gas testing to the ASTM E595 specification. In figure 4 below are the test results by NASA [ii]:

No weight loss was observed for MoS2 up to 1700' F (930' C). Beyond 1700' F (930' C), the weight loss rate increased with temperature. At 2000° F (1090' C), sulfur peaks were observed, indicating the liberation of sulfur because of thermal dissociation [ii]. Similar results were found from another experiment when heating MoS2 powder in vacuum to 1832' F (1000 C) and reported a constant weight loss rate at 1742' F (950' C) [iii].

WS2 began to have a detectable loss rate at 1600' F (870' C), and sulfur peaks were observed at 1900' F (1040' C). The rate-temperature slope for WS2 is less than that of MoS2.

References:

[i] VEST, C. E. (1993). LUBRICATION OF SPACECRAFT MECHANISMS. Johns Hopkins APL.

[ii] Brainard, W. A. (1969). THE THERMAL STABILITY AND THE FRICTION OF THE DISULFIDES, DISELINIDES, AND DITELLURIDES OF MOLYBDENUM AND TUNGSTEN IN VACUUM. NASA. Cleveland: Lewis Research Center.

[iii] Johnston, R. R. M.; and Moore, A. J. W.: Water Adsorption on Molybdenum Disulfide Containing Surface Contaminants. J. Phys. Chem., vol. 68, no. 11, Nov. 1964, pp. 3399-3405

[iv] Vazirisereshk MR, Martini A, Strubbe DA, Baykara MZ. Solid Lubrication with MoS2: A Review. Lubricants. 2019; 7(7):57.