FAST Custom Fixturing Initiative

At FAST, we have been using additive manufacturing since 2020 to grow our business, increase our quality, reduce our costs, and shorten lead-times. Once a fixture is designed, we are able to fabricate it in-house in less than 24hrs.

The end results have been outstanding: every part which has been "fixturized" has a 0% defect rate and 100% on-time delivery rate for our customers. Whenever possible, this type of fixturing is how we prefer to process parts.

Perfect for Safety Critical Parts.

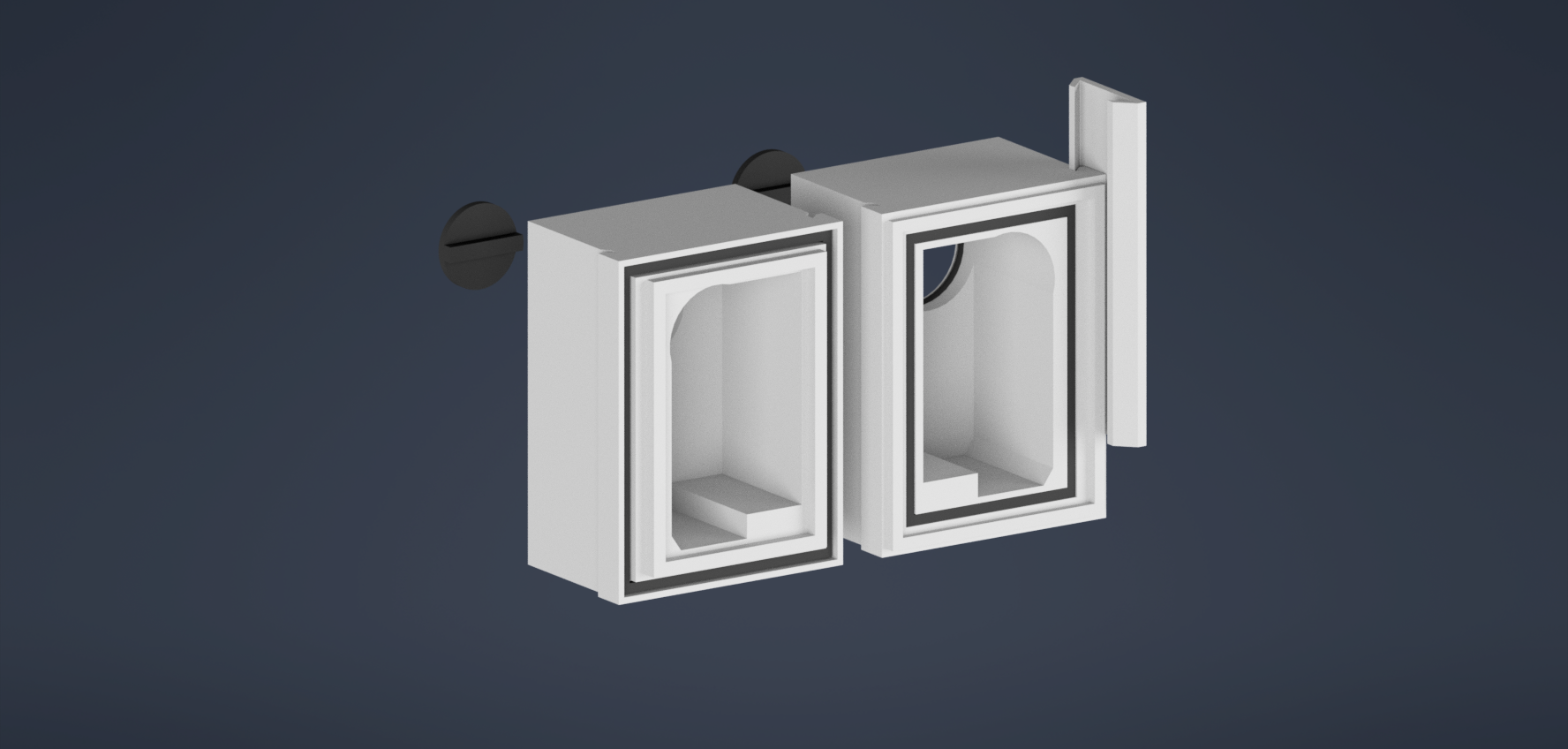

This fixture we use for processing small bearings where our customer only required the inside diameter coated. No over-spray is allowed on any outer surface.

Originally, we masked the whole part with tape and cut out the hole using razor blades. This time-consuming process often left tape residue on the parts after processing which needed to be cleaned off, as well as risked scratching the safety-critical inner diameter with the razor blades.

By designing our own fixture for these parts, we were able to eliminate tape residue on the parts and ensure that the critical area is never at risk of being scratched. We now produce fixtures for all of our safety critical parts which require masking, completely removing any chances of scratching or tape residue on crucial areas. This dedication to quality on safety critical parts is something unique to F.A.S.T. .

Since our fixtures completely seal off each part, the amount of time it takes to clean off parts after processing has been drastically reduced. The fixtures for these safety critical bearings above saved processing time and reduced the internal rework rate down to zero. The fixtures can be used repeatedly, and we have used each fixture over 100 times already. Because of these significant advancements, we were able to cut our lead-times and make our prices extremely competitive. For this top aerospace customer, we have provided a 100% quality rate and 100% on-time delivery for over 7000 pieces since 2020. In addition to this part, we have now acquired several other parts each with quantities in the thousands for processing, and the customer is now recommending us to their suppliers for outsourced work.

Unmatched Efficiency.

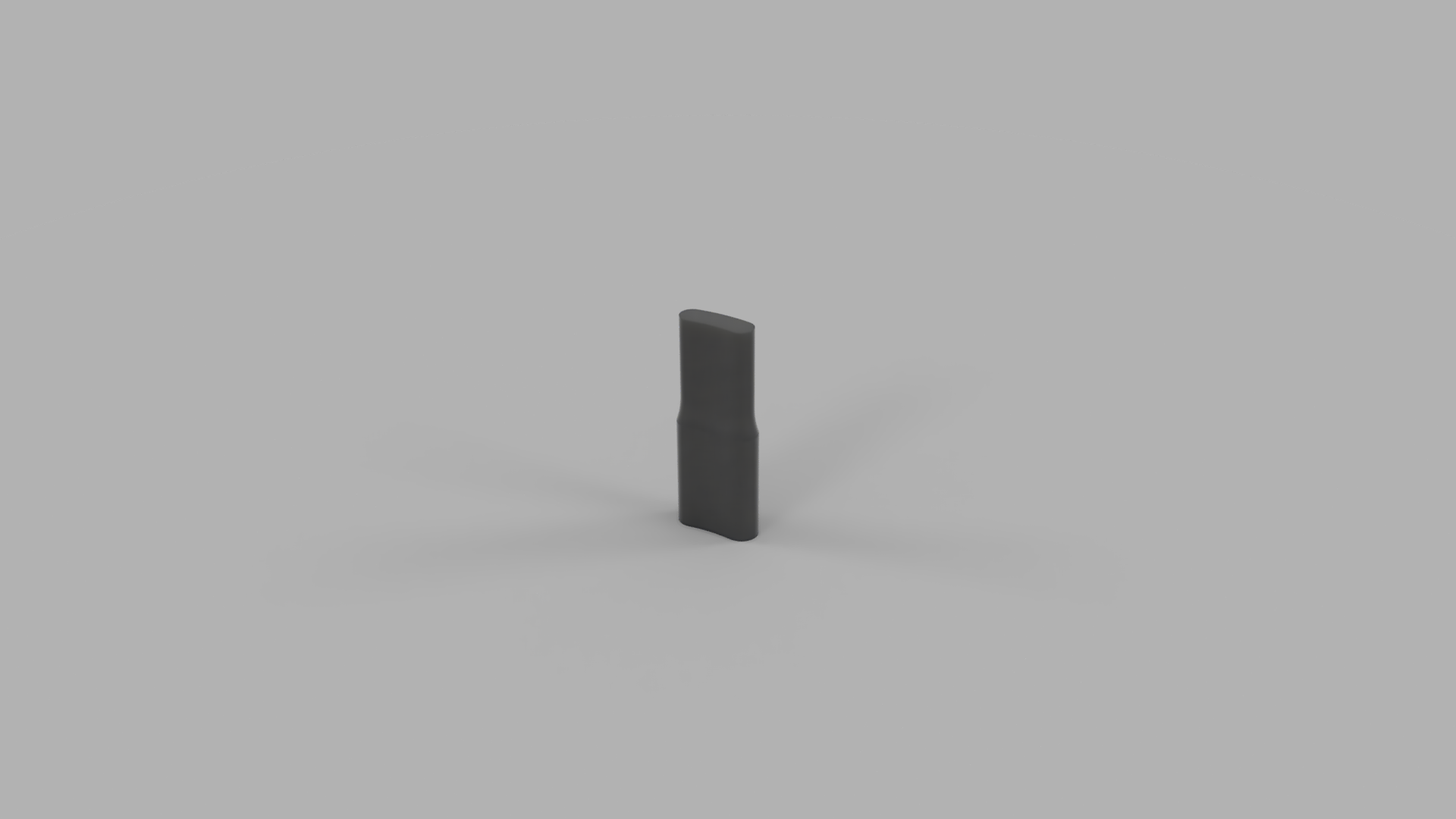

This masking design is for a lens barrel and is made out of a Thermoplastic Polyurethane (TPU) plastic. It has a shore hardness of 75A and can stretch 3 times more than its original length. Masking time using these flexible caps takes just seconds, a drastic improvement compared to the old method of taping and cutting out the inner diameter which took minutes apiece. After processing, these caps can be taken off just as quickly and reused on another part right away, with our oldest caps having been used over a dozen times already.

We were able to design this cap and fabricate over two dozen of them within 36 hours prior to our customer's order arriving, and were able to ship that order in less than 24 hours affer arrival.

Other Fixtures

A pair of flexible TPU end caps which thread directly onto a part to mask threads from WS2 coating.

Plugboards which enable operators to process multiple small parts at once, eliminating part droppage.

A custom-shaped pull plug made of 60A shore hardness TPU, used to prevent MoS2 coating in a small, curved slot.

A fixture with integrated gaskets which masks off the body of a highly irregular part, leaving only two cylindrical posts protruding for WS2 coating. The posts have slots in the end face which are masked by reusable TPU caps which snap into the slots.

A carrier which can hold over a dozen bearing races for mass cleaning in solvent tanks. This design is glue-less and made of polypropylene in order to resist chemical cleaners.

A case which masks off all but the threaded end of a long, thin rod for WS2 coating. Using precise spacers and various caps, numerous rod lengths can be processed with the same base design.

A cap made of flexible TPU which slides onto the end of a microscope barrel to mask it from WS2 coating.

A small two-part case with o-ring slots to mask off the center bore of a small disk-shaped part.

A large case to mask off all but the ends of a highly irregular shaft for WS2 coating. Features two end caps to seal off the top and bottom seams, and a flexible outer sleeve (not shown) to hold the case together and fully eliminate the use of tape.

A stack-able, scalable packaging case for long, thin machined parts which increased the density of parts per shipping box by 30% and reduced labor associated with packing and unpacking by over 50%.